Barcode Labels Manufacturers In India, Sticker Manufacturer

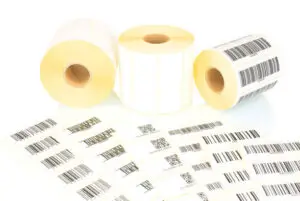

As a barcode labels manufacturers, Barcode International is specialize in producing barcode labels that are crucial for inventory management, retail operations, shipping, and more.

Looking For Barcode Labels Manufacturers In India?

In the dynamic realm of modern business operations, where efficiency and accuracy reign supreme, the humble barcode labels stands as a silent hero.

Behind every seamless inventory check, swift checkout process, and precise supply chain management lies a carefully crafted barcode label.

Let’s delve into the intricacies of barcode labels manufacturing and uncover why it’s pivotal for businesses across industries.

What Are Barcode Labels?

Barcode labels are specialized labels with machine-readable codes (usually 1D barcodes or 2D barcodes, such as QR codes) that store data, like product identification, pricing, and inventory information. These labels are used to automate data entry processes, track inventory, and streamline operations in industries like retail, healthcare, logistics, and manufacturing.

Barcode International is the Best Barcode Labels Manufacturers in India

Imagine a bustling warehouse where thousands of products move daily. Amidst this organized chaos, barcode labels serve as beacons of order.

Designed meticulously using specialized software, these labels encode essential information—product details, pricing, and unique identifiers—into a compact digital pattern.

Hence, this data is crucial for swift inventory checks, ensuring stock levels are monitored with precision.

Furthermore, from retail giants to small-scale enterprises, barcode labels manufacturers streamline operations, minimizing errors and maximizing efficiency.

How to Choose the Right Barcode Label Manufacturer?

When selecting a barcode label manufacturer, consider the following factors:

- Customization Options: Ensure the manufacturer can provide labels that meet your specific requirements, whether it’s custom size, material, or design.

- Material Durability: Choose manufacturers who offer labels made from durable materials like polyester, vinyl, or BOPP for long-lasting performance.

- Printing Technology: Ensure they offer the appropriate printing technologies (like flexographic or digital printing) that match your barcode needs.

- Compliance: The manufacturer should be compliant with industry standards (such as GS1 standards), ensuring that your labels are universally scannable.

- Turnaround Time: Depending on your business’s volume and urgency, consider a manufacturer with quick production times and fast delivery services.

- Cost-Effectiveness: Compare pricing and volume discounts. Opt for a manufacturer that offers competitive pricing without compromising quality.

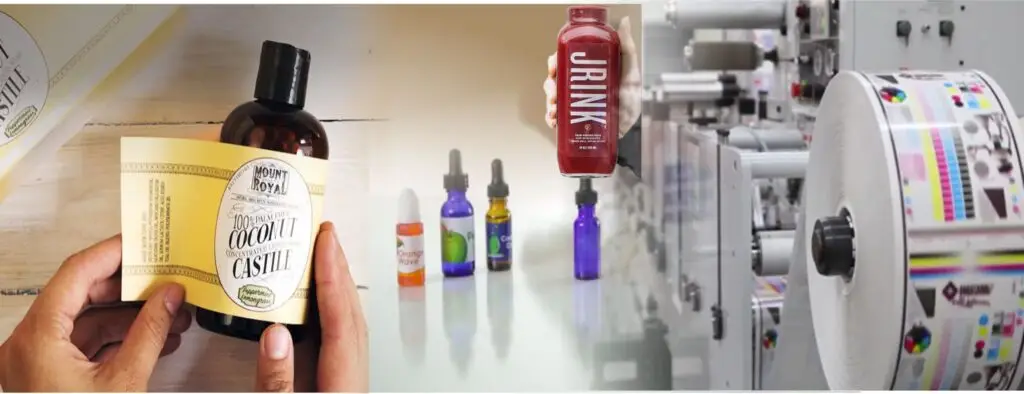

Deliver High Quality Barcode Labels For Your Industry

Eventually, manufacturing of barcode labels involves a symphony of technical expertise and meticulous craftsmanship.

It begins with selecting the right materials—rugged synthetics for outdoor durability, or specialized coatings for chemical resistance.

Generally, Precision printing methods, from thermal transfer to digital printing, ensure clarity and durability.

Additionally, Each label undergoes rigorous quality control, verifying scan ability and adherence to industry standards.

This commitment to excellence guarantees labels that perform flawlessly under diverse conditions, from the storeroom to the point of sale.

Barcode International is Driving Business Growth through Innovation

Beyond functionality, barcode labels manufacturers fuels innovation. Advanced technologies such as RFID tags and smart labels are revolutionizing inventory management, offering real-time tracking and enhanced data insights.

Customization options—from size and shape to color and finish—cater to diverse business needs, reinforcing brand identity while optimizing logistical processes.

Thus, Forward-thinking manufacturers continually push the boundaries of what’s possible, adapting labels to meet evolving industry regulations and customer expectations.

Barcode Labels Manufacturers in Delhi

In the fast-paced landscape of global commerce, partnering with a trusted barcode labels manufacturers is more than a transaction—it’s a strategic investment in operational excellence.

From initial design consultations to ongoing support, manufacturers provide invaluable expertise, ensuring labels not only meet but exceed expectations.

Moreover, With a finger on the pulse of industry trends and technological advancements, these partnerships drive business growth, empowering enterprises to navigate challenges and seize opportunities in an increasingly interconnected world.

Since, this post aims to highlight the significance of barcode labels manufacturers while emphasizing its role in enhancing operational efficiency and supporting business growth.

How Barcode Labels Manufacturers Process Flows?

Design and Production:

Firstly, creating barcode labels that meet industry standards (such as UPC, EAN, QR codes) using specialized software and printers.

Material Selection:

Secondly, choosing appropriate materials (paper, synthetic materials) based on durability requirements (waterproof, heat-resistant) and application (indoor, outdoor).

Customization:

Thirdly, offering customization options such as different sizes, colors, and adhesive types to suit various client needs.

Quality Assurance:

Fourthly, ensuring barcode labels are scannable and meet accuracy standards to prevent scanning errors in logistics and retail environments.

Compliance:

Lastly, Adhering to international standards (GS1, ISO) to ensure compatibility with scanners and systems worldwide.

Customer Service:

Additionally, as a barcode labels manufacturers, Barcode International Provide support for barcode specifications, label design, and troubleshooting issues related to label printing and scanning.

Innovation:

Although, keeping up with advancements in barcode technology and offering new solutions like RFID tags or specialty labels for niche markets.

Overall, your business plays a crucial role in supply chain efficiency and retail operations by providing reliable and accurate identification and tracking solutions through barcode labels.

In addition, in today’s fast-paced world of logistics and retail, efficiency is key. Barcode labels play a crucial role in streamlining operations and enhancing accuracy. Here’s why they matter:

🔍 Precision Tracking: Each barcode contains unique data that identifies products, enabling precise tracking from manufacture to sale.

📦 Inventory Management: Simplify inventory processes with barcode scanning, reducing errors and improving stock accuracy.

🛒 Enhanced Customer Experience: Swift checkout processes and accurate product information improve customer satisfaction.

🔄 Operational Efficiency: Speed up workflows in warehouses and retail stores, optimizing supply chain operations.

📈 Business Insights: In order to analyze sales trends and inventory turnover with data collected from barcode scans.

🔒 Security: Ensure authenticity and prevent counterfeiting with secure barcode labeling solutions.

🔗 Integration: Seamlessly integrate barcode systems with existing software for enhanced automation.

From groceries to global shipments, barcode labels are the unsung heroes of modern commerce. Embrace the power of efficiency today!

Contact Us For Barcode Labels, Printed Labels Needs

Barcode labels manufacturing is more than just printing stickers—it’s a cornerstone of efficiency, accuracy, and growth for businesses worldwide.

Hence, by harnessing cutting-edge technologies and unwavering commitment to quality, manufacturers empower enterprises to streamline operations, enhance customer experiences, and stay ahead of the curve in a competitive marketplace. As businesses continue to evolve, the barcode label remains an indispensable tool, transforming data into actionable insights and propelling success across industries.

Above all, barcode labels manufacturers act as your catalyst for operational excellence and embark on a journey towards seamless efficiency today.

- Hook: Start with a compelling fact or statistic about the importance of barcode labels in modern business operations.

- Brief Overview: Introduce what barcode labels are and why selecting a high-quality manufacturer is crucial.

How to choose the Best Barcode Labels Manufacturers

1. Understanding Barcode Labels

- Definition: Explain what barcode labels are and their primary functions.

- Types of Barcode Labels: Describe different types such as thermal labels, RFID labels, and direct thermal labels.

- Applications: Discuss common uses in various industries (retail, logistics, healthcare).

2. Key Factors to Consider When Choosing a Barcode Labels Manufacturer

- Quality of Materials: Highlight the importance of durable and high-quality materials for barcode labels.

- Printing Technology: Discuss the different printing technologies (thermal transfer, direct thermal) and their impact on label quality.

- Customization Options: Explain the importance of customization in terms of size, design, and barcode symbology.

- Compliance and Standards: Mention industry standards and regulatory compliance (e.g., GS1 standards).

- Cost vs. Value: Provide insights on balancing cost with the quality and reliability of the labels.

3. How to Evaluate Barcode Labels Manufacturers

- Customer Reviews and Testimonials: Explain how to use customer feedback to assess quality.

- Case Studies: Share examples of successful implementations and satisfied clients.

- Certifications and Awards: List important certifications (ISO, UL) and awards that indicate reliability.

4. Trends and Innovations in Barcode Labeling

- Technological Advances: Discuss new technologies in barcode printing and materials.

- Future Trends: Predict upcoming trends, such as increased use of smart labels or integration with IoT.

5. Tips for Successful Label Ordering

- Sample Requests: Advise on requesting samples before bulk orders.

- Order Quantities: Provide tips on managing order quantities and reordering processes.

- Supplier Communication: Offer advice on effective communication with manufacturers to ensure all needs are met.

Industry Applications

Barcode labels are ubiquitous across industries, serving critical functions in:

- Retail: Facilitating efficient checkout processes, managing inventory, and ensuring accurate pricing and product information.

- Logistics and Warehousing: Streamlining inventory management, optimizing picking and packing processes, and enhancing supply chain visibility.

- Healthcare: Improving patient safety through accurate medication administration, tracking medical equipment, and managing inventory of pharmaceuticals and medical supplies.

- Manufacturing: Enhancing traceability, monitoring production processes, and ensuring quality control throughout manufacturing operations.

- Automotive: Supporting traceability of parts and components, managing inventory in assembly plants, and enhancing logistics efficiency across global supply chains.

Innovations Driving the Future

As technology advances we also manufacture barcode labels that continue to innovate:

- RFID Integration: Combining RFID (Radio Frequency Identification) with barcode labels for enhanced data capture capabilities and real-time tracking of assets and inventory.

- Smart Labels: Incorporating Near Field Communication (NFC) and IoT (Internet of Things) technologies to enable interactive consumer engagement and product authentication.

- Sustainability Initiatives: Developing eco-friendly label materials and adopting sustainable manufacturing practices to reduce environmental impact.

FAQs

What are the most important factors to consider when choosing a barcode label manufacturer?

When choosing a barcode label manufacturer, consider the following key factors:

- Quality of Labels: Ensure the labels are durable and suitable for your specific application (e.g., exposure to moisture, temperature, or chemicals).

- Print Technology: Look for manufacturers that use reliable printing technologies, such as thermal transfer or direct thermal, depending on your needs.

- Material Options: Assess the variety of label materials available, including paper, synthetic, and specialty materials, to ensure they fit your requirements.

- Adhesive Types: Consider the types of adhesives offered, especially if you need labels that will stick to various surfaces or withstand specific conditions.

- Customization Capabilities: Check if the manufacturer can produce custom sizes, shapes, and designs, as well as specific barcode types (like QR codes or UPC).

- Order Volume and Scalability: Ensure they can handle both small and large orders and can scale with your needs as your business grows.

- Lead Time and Reliability: Inquire about production and delivery times to ensure they can meet your deadlines consistently.

- Cost and Pricing Structure: Get quotes from multiple manufacturers and compare pricing, but also consider the value of quality and service.

- Customer Support: Assess the level of customer service they provide, including technical support, to help troubleshoot any issues.

- Reputation and Reviews: Research the manufacturer’s reputation through customer reviews, case studies, or testimonials to gauge their reliability and quality.

- Sustainability Practices: If important to your business, consider manufacturers that offer eco-friendly materials or sustainable production processes.

- Technical Expertise: Generally, look for manufacturers with expertise in barcode technology and can provide insights or recommendations based on your needs.

How do I know if a barcode label manufacturer is reliable?

To determine if a barcode label manufacturer is reliable, consider the following steps:

- Research and Reviews: Look for customer reviews and testimonials online. Check industry-specific forums, social media, and review sites for feedback on their products and services.

- References: Ask the manufacturer for references from current or past clients. Contact these references to gain insight into their experiences.

- Experience and Expertise: Evaluate how long the manufacturer has been in the industry. A company with a solid track record is likely to be more reliable.

- Certifications and Standards: Check if the manufacturer adheres to industry standards (e.g., ISO certifications). This can be a good indicator of their commitment to quality.

- Sample Orders: Request sample labels to assess the quality of their products firsthand. This can also give you an idea of their printing and material capabilities.

- Customer Service: Evaluate their customer support. A responsive and knowledgeable team is essential for addressing concerns and ensuring a smooth ordering process.

- Production Capabilities: Inquire about their production processes, technologies, and equipment. A manufacturer that uses modern and efficient technology is often more reliable.

- Lead Times: Check their turnaround times for orders. Reliable manufacturers should provide clear timelines and meet delivery commitments consistently.

- Communication: Assess how well they communicate during the inquiry and ordering process. Clear, timely communication is crucial for building trust.

- After-Sales Support: Inquire about their policies on support after the sale. A good manufacturer should be willing to assist with any issues or questions that arise post-purchase.

- Return and Warranty Policies: Understand their return policy and warranty for defects. A reliable manufacturer should stand behind their products.

- Industry Reputation: Look for any awards, certifications, or recognitions the manufacturer has received within the industry, which can indicate reliability.

What are the latest trends in barcode labeling technology?

The barcode labeling technology landscape is continually evolving. Here are some of the latest trends:

- 2D Barcodes and QR Codes: The use of 2D barcodes, particularly QR codes, is growing due to their ability to store more information than traditional 1D barcodes. They are increasingly used in marketing and product tracking.

- Smart Labels and NFC: Near Field Communication (NFC) technology is being integrated into labels, allowing for interactive experiences. Consumers can tap their smartphones on NFC-enabled labels to access product information or promotions.

- Sustainability: There is a growing demand for eco-friendly labeling solutions, including recyclable materials and biodegradable inks. Manufacturers are focusing on sustainable practices in production.

- Automation and IoT Integration: Automated labeling systems are becoming more prevalent, particularly in warehousing and logistics. Integration with Internet of Things (IoT) devices allows for real-time tracking and inventory management.

- Digital Printing: Digital printing technology is advancing, enabling high-quality, short-run printing of labels. This trend allows for greater customization and flexibility in design.

- Augmented Reality (AR): Some companies are incorporating AR into barcode labeling, allowing consumers to scan a barcode and receive immersive content or interactive experiences about the product.

- Data Analytics and Cloud Solutions: Advanced data analytics are being utilized to track product movements and consumer interactions. Cloud-based solutions enable easier management and accessibility of labeling data.

- Enhanced Security Features: With the rise in counterfeiting, manufacturers are incorporating security features into barcodes, such as tamper-evident materials and authentication technologies.

- Mobile Labeling Solutions: Mobile apps and handheld devices for label printing and scanning are gaining popularity, especially in retail and warehousing environments, enhancing flexibility and efficiency.

- Cross-Platform Compatibility: Increased focus on ensuring that barcode systems work seamlessly across various platforms and devices to improve user experience and data accessibility.

Conclusion

In conclusion, barcode labels manufacturers play a vital role in modern commerce by enabling efficient inventory management, enhancing supply chain visibility, and ensuring product authenticity and traceability.

As industries evolve and consumer expectations rise, these manufacturers continue to innovate, providing customizable solutions that meet diverse industry needs while driving efficiency, reliability, and sustainability in product identification and tracking systems globally.

Hence, their contributions not only streamline operations but also empower businesses to adapt and thrive in an increasingly interconnected and competitive marketplace.

- Mobile: +91-8700346392

- Mail: sales@barcodeinternational.in

Label Manufacturer in Haryana

[…] Barcode Labels Manufacturers […]